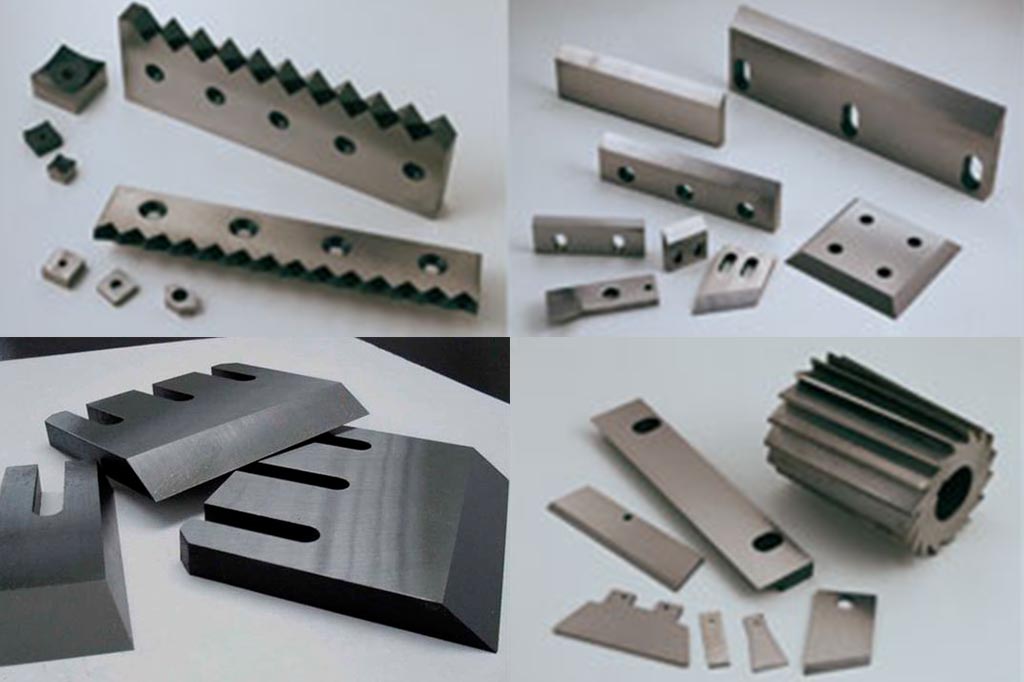

Industrial blades

The first step is the selection of the best qualities and the most suitable raw materials for each type of blade quality. We work with the most prestigious steelmakers in the world: Thyssenkrupp and Böhler. We have a stock of more than 150 tons, which help us to offer our customers the shortest delivery terms.

For the machining phase, we have two automatic belt saws and 4 milling centers.

The metal-tempering is the most critical process, since it will determine the final physical properties of the blade. We have 10 quenching and tempering furnaces, which allow us to make a customized heat treatment for every need, achieving the perfect balance between hardness and toughness and giving each blade maximum performance. Once the manufacturing process is completed, each blade is subjected to a rigorous quality control to verify that the hardness is correct.

Our goal is to make the best blade for each recycling process. Our challenge is to propose effective alternatives to generate maximum value to our customers. We study each case, from the machine to the material to be processed to obtain the perfect balance to provide maximum performance. As specialists in blades for recycling, we know and apply the exact specifications required by each sector and each process.